The valve industry is growing every day, and with this growth, more and more people are learning about the amazing opportunity to work in valves. Many new individuals entering the industry do not, however, know the first thing about valves. The first thing that should be understood is that no one learns about valves until they work with them. There is no Bachelor of Science degree for valves, and anyone involved with them had to learn from scratch at one time or another. It is, therefore, useful to have a ‘cheat sheet’, or guide, to reference for individuals entering the industry, on everything they may need to quote valves.

By Chance Russo, Director of Valve Products – Sesto Valves

Before looking at valve specifics, individuals working with valves should keep this in mind; when one receives a Request for Quote (RFQ) from a customer, the first thing that needs to be determined is if there are any specifications or data sheets attached to the inquiry. Having clear specifications and/ or data sheets makes quoting valves much easier. The majority of the inquiries will not, however, have specifications attached. It is in this circumstance that a guide becomes necessary; it will provide all the necessary steps to ensure a proper quote can be submitted.

Seven Elements

There are 7 key considerations required for an individual to obtain adequate information to offer a quotation.

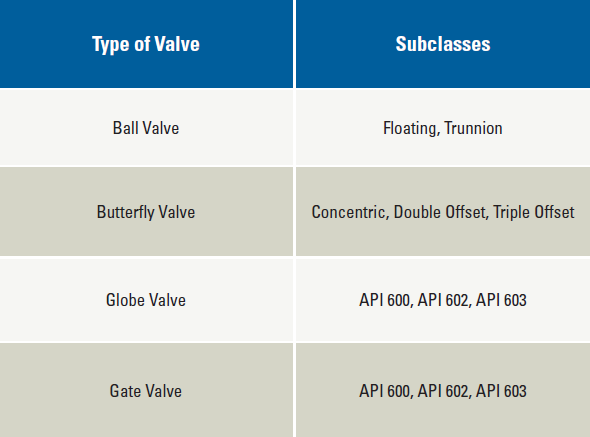

1 – Type of Valve

While there are many types of valves, this guide will highlight the four main types of block or isolation valves. These include ball, butterfly, gate, and globe valves. Each valve type has several additional specific valves that are identified, refer to Figure 1. The first step to creating a viable quotation is identifying the correct valve type.

2 – Size or Diameter

This is quite simple. One needs to make sure that the customer gives the size in inches that they need. This can range anywhere from 1/4” to 48” or larger. Typical sizes include 1/4”, 3/8”, 1/2”, 3/4”, 1”, 1-1/4”, 1-1/2”, 2”, 2-1/2”, 3”, 4”, 5”, 6”, 8”, 10”, 12”, 14”, 16”, 18”, 20”, 24”, 28”, 30”, 36”, 42”, 48”, etc. Some valves with European configurations can give a metric size that is denoted as DN. An example would be DN25 which would be equivalent to a 1” size.

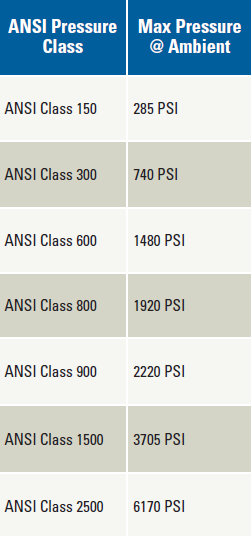

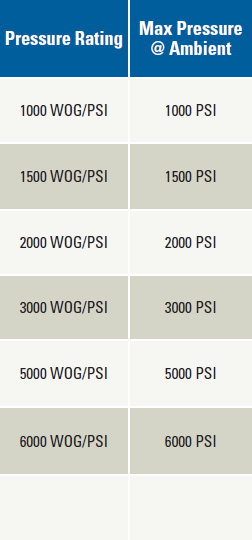

3 – Pressure Rating or Class

The pressure class of the valve can be measured in one of two ways. There are ANSI Class denominations or working pressure ratings (WOG/PSI). The common ANSI class ratings and WOG or PSI pressure ratings are shown in the table below. The valve must have a pressure rating to quote.

4 – End Connections

Valves can be installed in many configurations and the end connections will denote how they are to fi t into the piping. Some of the most common end connections include: RF Flanged, RTJ Flanged, FF Flanged, NPT (Threaded), SW (Socketweld), BW (Buttweld), Wafer, or Lug. It is critical that the end connections are established as failure to do so could result in the valve not fitting.

5 – Body Material

The material of construction of the body, which includes any closures or bonnets, must also be known. This is the material that will be seen if looking at the valve. Think of it as the structure or casing of the valve’s working components. Typically, most valves will be either Cast Iron, Ductile Iron, Brass, Bronze, Carbon Steel, or Stainless Steel. There are several material designations for each type of material and having the exact code (for example ASTM A216 GR WCB Carbon Steel), is helpful in quoting.

6 – Trim Material

Trim material is the material for the internal components of the valve. These internal components are the working parts of the valve. Different valve types have different internal components, but all of them have three basic components: a part that turns the flow-blocking component, the flow-blocking component, and the sealing component. The device that turns the obturator or blocking part is typically a shaft or stem. The obturator can be a ball, disc, wedge gate, or plug. The sealing components are always called the seats of the valve.

The trim is therefore the material of these three parts. A typical valve will say Stainless Steel trim, but they may call out the material of each individual part. Seats can be metallic, rubber/ plastic, or soft types such as Teflon. It is very important that the requirement for the seat material is specifically called out and noted on the request. For gate and globe valves, there is a list of API 600 trim codes that can be found on the internet.

7 – Operator

All isolation or block valves can be either manually operated or automated. Manual operators can be a lever, wrench, hand wheel, or gear operated. Automated operators include pneumatic, electric, hydraulic, hydroelectric, etc. If the customer wants to choose their own operator, they may request the valve as ‘bare stem’ which means they want the valve without any operator.

Final Thoughts

Once these seven common components of the valve are determined, there will be enough information to send a manufacturer the request for a quote. While it is not a thorough understanding of the principles and mechanisms of how valves work, it will provide the manufacture with sufficient information.

Now, this is only a basic guide as there are many other features that can be called out or required. It is important to remember that acquiring any additional information will be helpful in determining and quoting the right valve for the right application. Always ask the customer if they have any additional information such as specifications or data sheets.