What do successful organizations, large and small, have in common? When they are confronted with required changes to their operating systems, based on new governmental regulations, they have little recourse other than to find a solution.

By Bob Connal, Managing Director – Hybrid Automation Inc.

On January 20, 2021, President Biden issued Executive Order 13990. It directs the EPA to issue new regulations under the Clean Air Act, to significantly reduce oil/gas producers’ methane emissions. This Executive Order (EO) provides the EPA with the power to develop, implement, and enforce industry-changing restrictions on methane emissions at multiple levels throughout the natural gas production chain. It includes specific wording which identifies the conversion of pneumatic controllers to zero-emitting technologies and the elimination of associated gas venting. The proposal would regulate, for the first time, methane-driven pneumatic controllers which vent methane directly to the atmosphere on every stroke

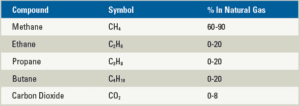

Methane Use by Producers

Methane (natural gas) is a common product, or by-product, of wells that are put into production. This methane is frequently under high pressure directly out of the ground either naturally or as a result of injection techniques used to increase liquid/gas production. For decades, it has been a common practice by producers to use this gas as a source of power, via pressure, to control pneumatic actuators. Applications for this ‘free’ source of power touch all levels of natural gas production; be it up-stream, mid-stream, or down-stream.

When gas-powered pneumatics actuators are stroked, methane is vented directly into the atmosphere. Reducing methane releases to the atmosphere from methane-powered pneumatics will continue to be a contentious topic, regardless of who sits in the White House.

Producer Options

Solutions to mitigate methane fugitive emissions are complex. Oil & gas producers have invested heavily in R&D to address existing and new EPA/Clean Air Act regulatory directives. Few viable, cost-effective, options have surfaced for producers, as they must consider multiple options best suited for individual site locations.

The issues to retrofit existing methane-powered pneumatics can range from a total automated valve replacement to new technologies which enable the existing valve and actuator to remain intact. There is no blanket solution to methane mitigation. As unique as each well is, so will be the solution.

Access to reliable electric power will also become an important component for long-term success in methane mitigation. The use of failsafe actuation (electric and pneumatic) may play a larger role in valve automation for natural gas pipelines, however, it is too early to tell.

If a gas pipeline needs to shut down for a new zero-emissions valve automation retro-fit, it could come at a significate loss of revenue to the producer. Long-term solutions need to be cost-effective, reliable, maintenance-free, easy to implement, and provide tangible results mitigating methane venting to the atmosphere. Producers with a proactive approach to addressing EO 13990, benefit from a positive dialog with the EPA and environmental activists.

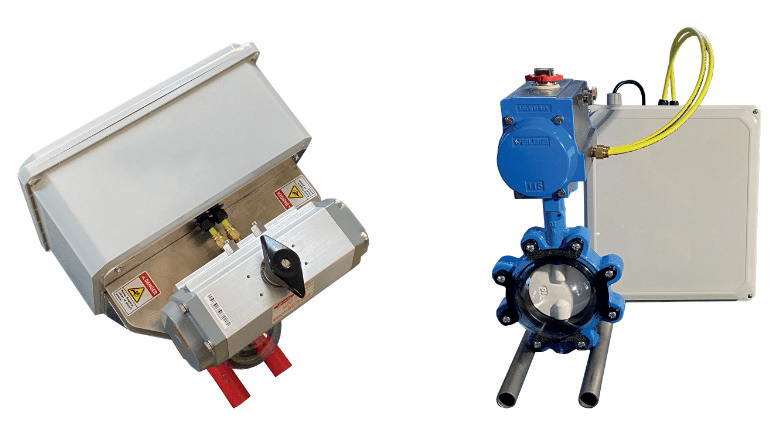

The Solution

Technology currently exists which converts existing methane-powered pneumatic actuators to a zero vent-to-atmosphere operating system. Based on a simplistic operating platform, compressed air flows between an accumulator and the existing pneumatic actuator. With a closed-loop operating platform, there is zero reliance on external sources of pressure. Air lines from the Hybrid Automation controller connect directly to the intake and exhaust ports of the existing pneumatic actuator. This technology eliminates methane as a means to power existing actuators, regardless of pneumatic manufacturer or actuator type. If the existing pneumatic is single-acting, it will continue to function as a single-acting (fail-safe) device.

System reliability and maintenance-free technology play an important role in a producer’s decision-making process. Duration testing of this technology has shown zero failures after 200,000+ consecutive cycles in failsafe mode. The new closed-loop technology has no printed circuit boards, software, batteries, or oil reservoirs and the operating system is based on the volumetric displacement of the pneumatic actuator; it can provide any psi operating pressure recommended by the actuator manufacturer. Ambient air or an inert gas can be used to provide the initial charging of the controller. Once charged, the controller requires no additional source of air. No venting to the atmosphere, zero fugitive emissions, totally closed loop.

This technology provides immediate, tangible results to oil/gas producers who have established ESG directives and goals. Reducing greenhouse gas emissions through smart technology is not a fad. It has worldwide implications for improving the health of individuals and the environment. Hybrid Automation does not manufacture valves or actuators, and it does not flare methane. Reducing fugitive methane emissions throughout natural gas production is smart business. Additional cost-effective methane mitigation technologies will continue to evolve.

Hybrid Automation is proud to be a technology innovator in cost-effective methane mitigation. It follows a proven engineering model based on the following statement: “The best-engineered products have the fewest number of moving parts.”